Start with establishing a strategy that suits your machine’s capability. Some presses have better control of mold protection, you may want to ensure your delicate molds go only in those machines. To protect the mold from any obstruction, whether a part or delicate mold detail such as a horn pin, that prevents smooth mold closing.

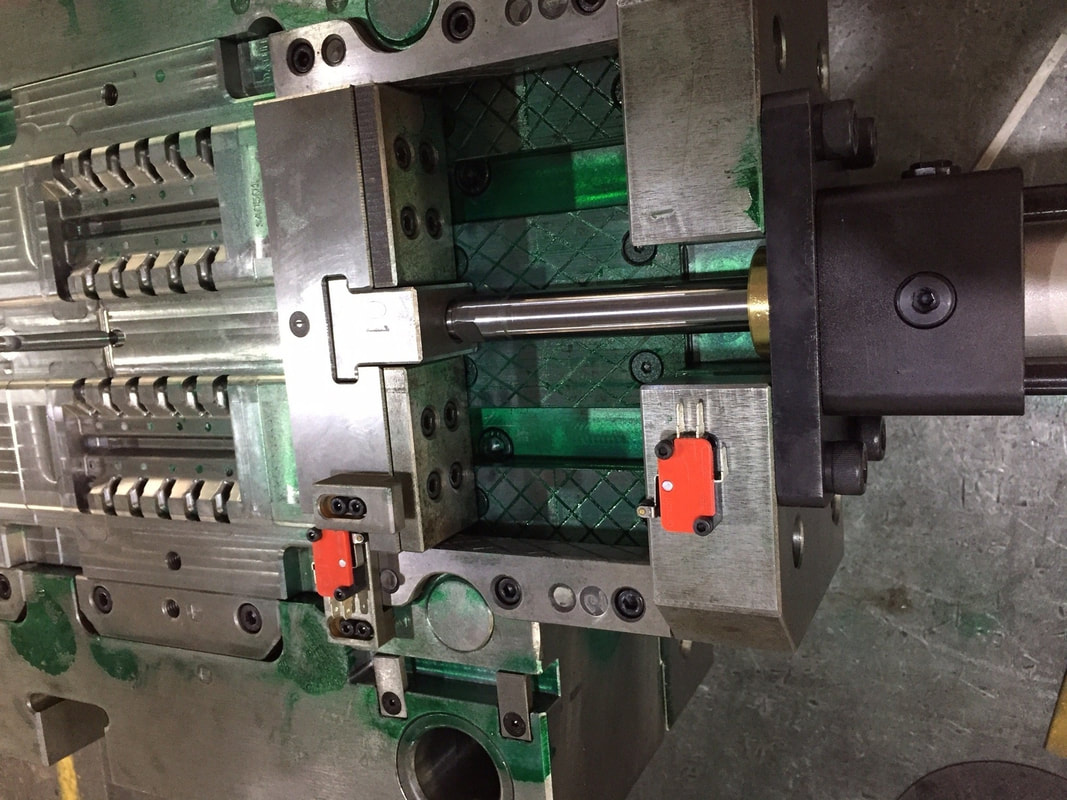

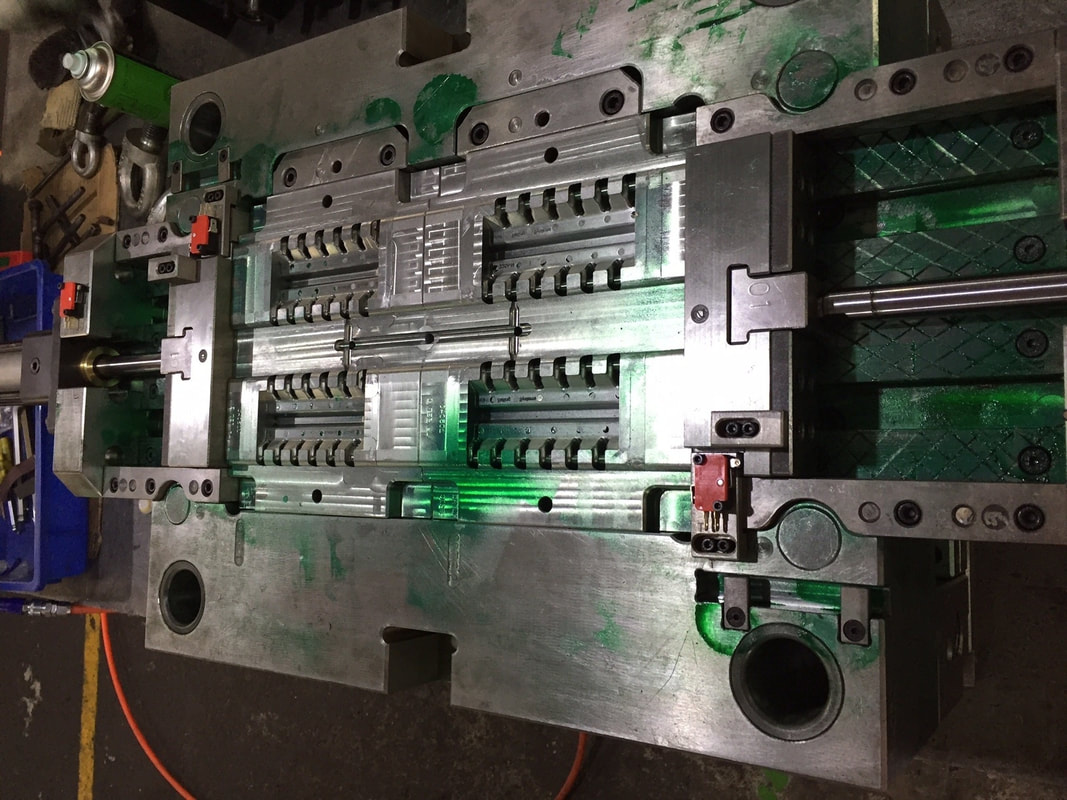

Set mold protection to be on during the entire mold-closing cycle if you have a machine that can monitor the entire stroke and will stop and alarm is anything is out of a normal band. Otherwise, set mold protection to start a little before the moving side touches a delicate mold detail, horn pin, slide, or possible obstruction.With microswitches, as photos, at starting cycle to be designed on plastic injection mold.

RSS Feed

RSS Feed