| Molding Flashes debug ! It occurs when a thin layer of material is forced out of the mold cavity at the parting line or ejector pins location. Causes:- @ worn or poorly fitting parting surface, including mold plate deformations and obstructions (grease,dirt, debris). @insufficient clamp force of which mold plates shut off are not holding sufficiently. @ over-packing on sections, thus increasing localized pressure. @ non-optimal molding conditions, including material viscosity, injection rate, mold temp. and runner system, etc. @ improper venting due to poor designed venting system. Solutions: # ensure correctly fitting mold plates, set up the mold to seal properly, clean the machine from any obstructions, add pillar or thicken the mold plates if there is any deformation of the mold plate during molding process. # avoid over packing # select machine with higher clamp force #vent effectively, especially at materials joining lines # optimize processing conditions with reducing pressure and shot size to the minimum required. |

|

0 Comments

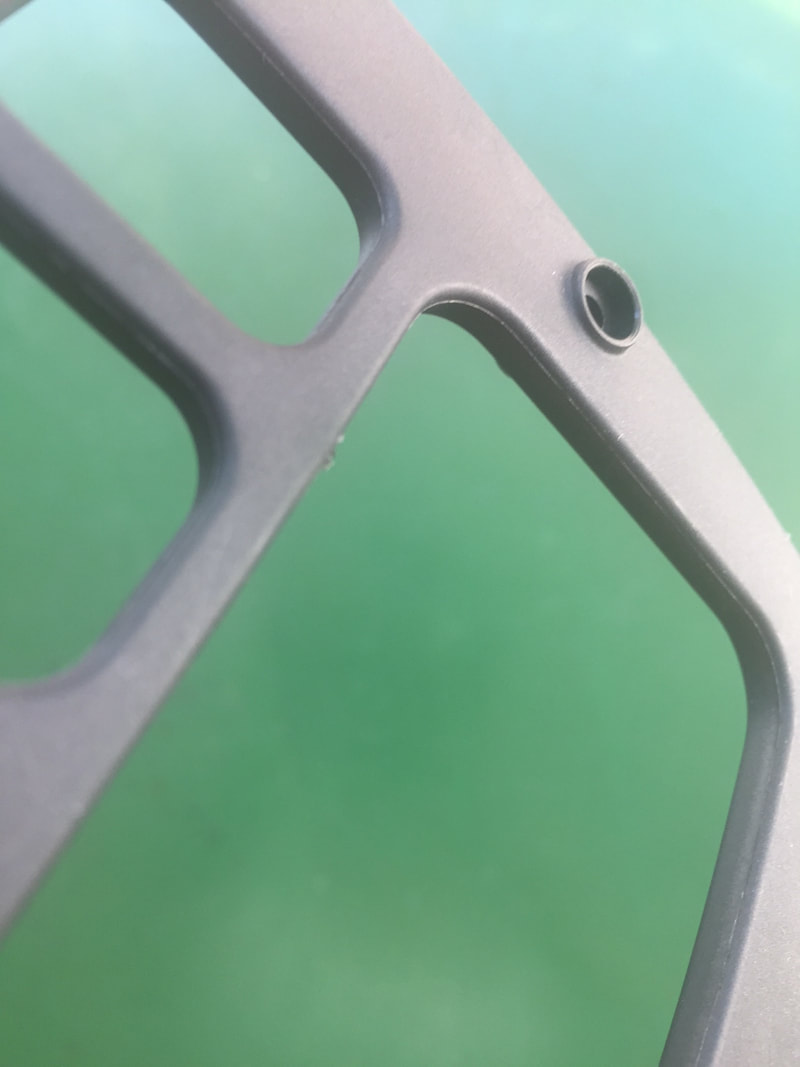

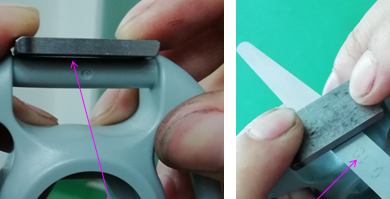

Plastic Part Deformation in control from START in plastic part design !?

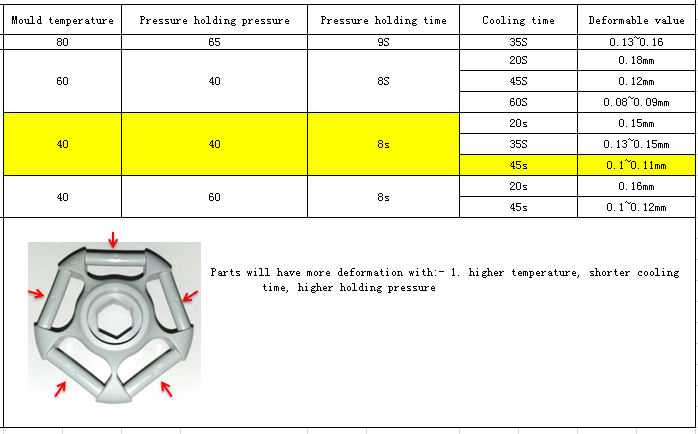

Plastic design, mold design, plastic materials selection and injection parameters are the 4 keys in affecting final plastic part deformation. The plastic part design is dominated the others. With uneven wall thickness and differential shrinkage at different locations: - mold design and raw plastic materials will make up a little effect, - injection molding parameters setting will then be more demanding for reducing deformation of parts under constant part weight and tool gating size by means of @ lower mold temperature @ longer cooling time @ lower holding pressure |

AuthorWorking in plastic injection mold making and molding over 20 years. Archives

March 2024

Categories

All

|

RSS Feed

RSS Feed