|

For this new year of Rooster, we look forward to having new business with you by offering free of charge enquiry, DFM report and mold flow analysis in all your new projects from conceptual design to manufacturing and in production to markets as one fully support solutions. Click here to review www.injectionmoldingsupplier..com

0 Comments

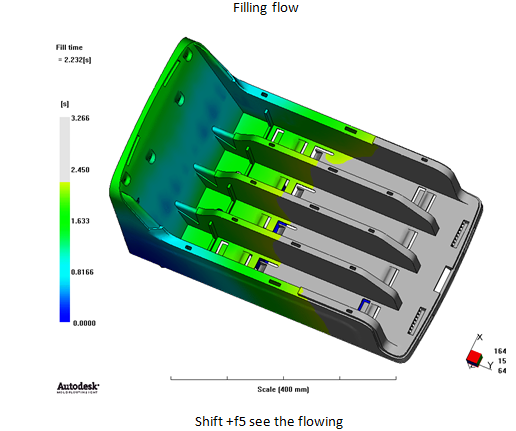

We encountered thin tooling steel deformation by injection molding pressure.

Under plastic part functional and cosmetic constraints, we did mold flow analysis integrated with part re-design with internal by-pass ribs. Its perfect balancing of plastic materials flow on both sides of thin steels inserts, thus avoiding thin steel deformation, It resulted in successful perfect plastic injection part in limited time launching to market.  In past, it took time to glue and manually inserted bristles as products completion. Require lot of manpower with instable quality. Now, we make complete automation(elimination of manpower for bristles plantation) with insertion of stainless wire plate (elimination of glue) to hold PBT bristles (dia 0.05mm) mechanically tight in constantly high quality. TSY Molding Limited always co-works with client for cost saving solution with improving quality from start to after production services. This is why we gain long term clients globally with total customers' satisfaction. |

AuthorWorking in plastic injection mold making and molding over 20 years. Archives

March 2024

Categories

All

|

RSS Feed

RSS Feed