Plastic Injection Molding Design Guides:-

This design guide for plastic injection molding may be helpful to an experienced design engineer or one just starter with injection molding.

@ basic principles of injection molding and benefits , limitations and applications.

@Optimize your parts for plastic injection molding

@Consideration to reduce cost of your future projects

@Optimize your parts for plastic injection molding

@Consideration to reduce cost of your future projects

Selection of plastic injection tool

Prototyping toolsTool shot life - arond 1k

shorter manufacturing time Cost efficient in mold only, but higher cost at high volume molding run. |

Production toolsTool shot life-100k to 1M shots

longer manufacturing time Cost efficiency at higher volume, mostly at automatic production. |

Selection of plastic injection molding materials

Plastic Materials & Properties

ABS, PC, HIPS Cosmetic

ABS, PMMA, PVC, PE, PC Impact Resistance

POM, PEEK Wear Resistant

PP, PE, PA,PEEK Chemical Resistance

ABS,PPS,HIPS,PBT Dimensional Stability

PP, HDPE, LDPE Cost economy

TPU,TPE,Silicone Rubbber feel

ABS, PMMA, PVC, PE, PC Impact Resistance

POM, PEEK Wear Resistant

PP, PE, PA,PEEK Chemical Resistance

ABS,PPS,HIPS,PBT Dimensional Stability

PP, HDPE, LDPE Cost economy

TPU,TPE,Silicone Rubbber feel

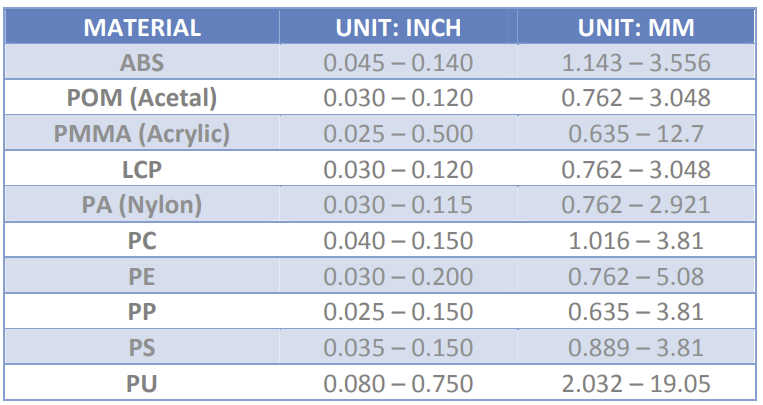

Recommended Wall Thickness

Only reference for general thickness with a molded part. Specific part geometry, say ribs, will affect thickness.

MOLDS and PARTS identification

Each cavity is marked with the number or letter.

It will be applied for molds with more than 1 cavity.

Proposal of marking area will be sent to you before mold production.

It will be applied for molds with more than 1 cavity.

Proposal of marking area will be sent to you before mold production.

Injection moulding surface finish

It is critical to a successful part design and used for aesthetic and functional reasons.

Two main standards: VDI 3400 , SPI

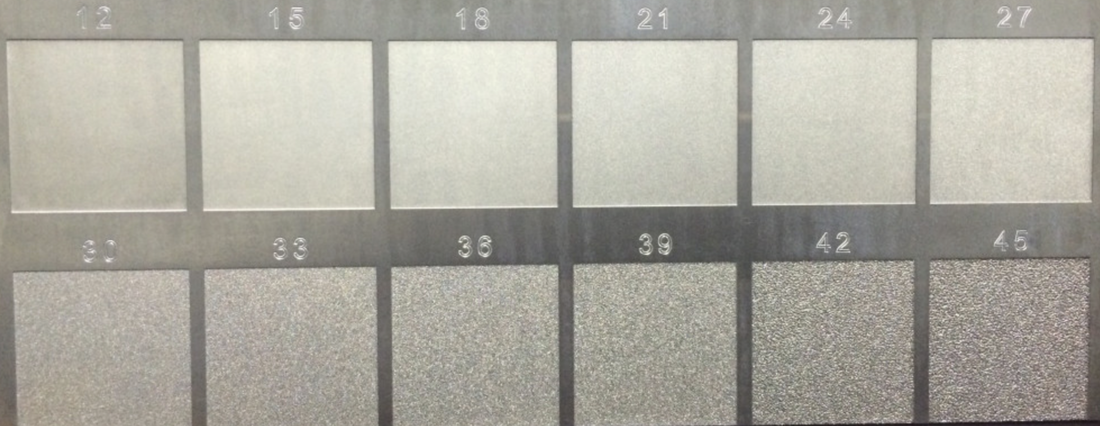

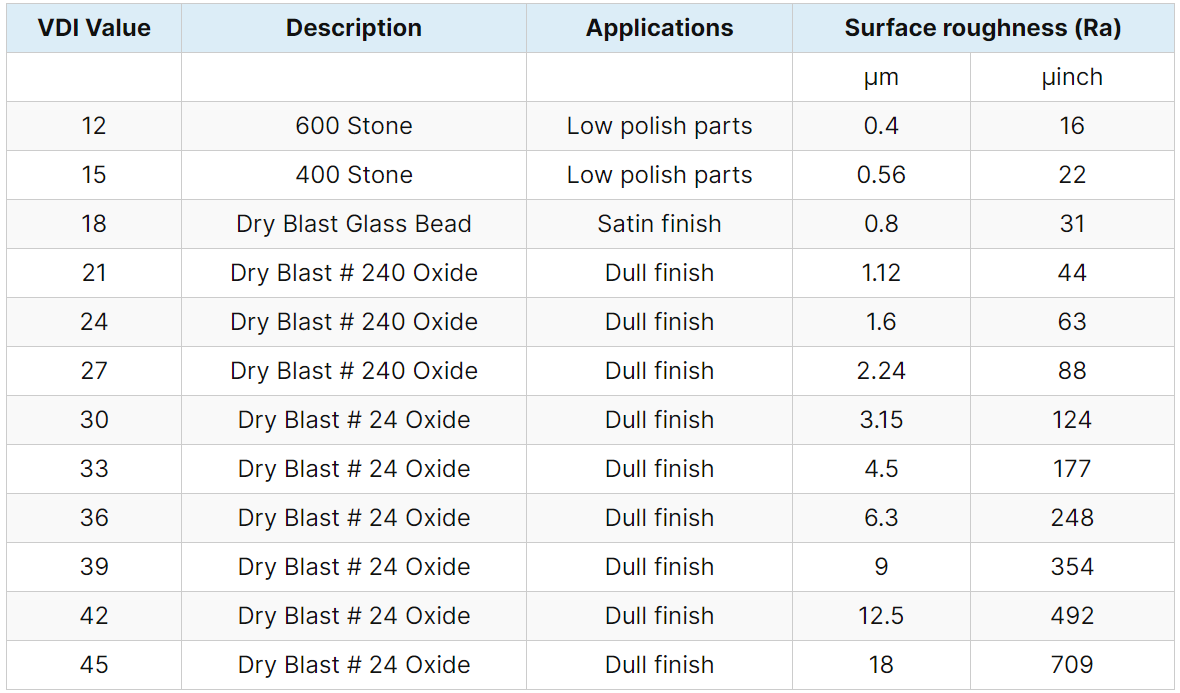

VDI 3400 surface finish

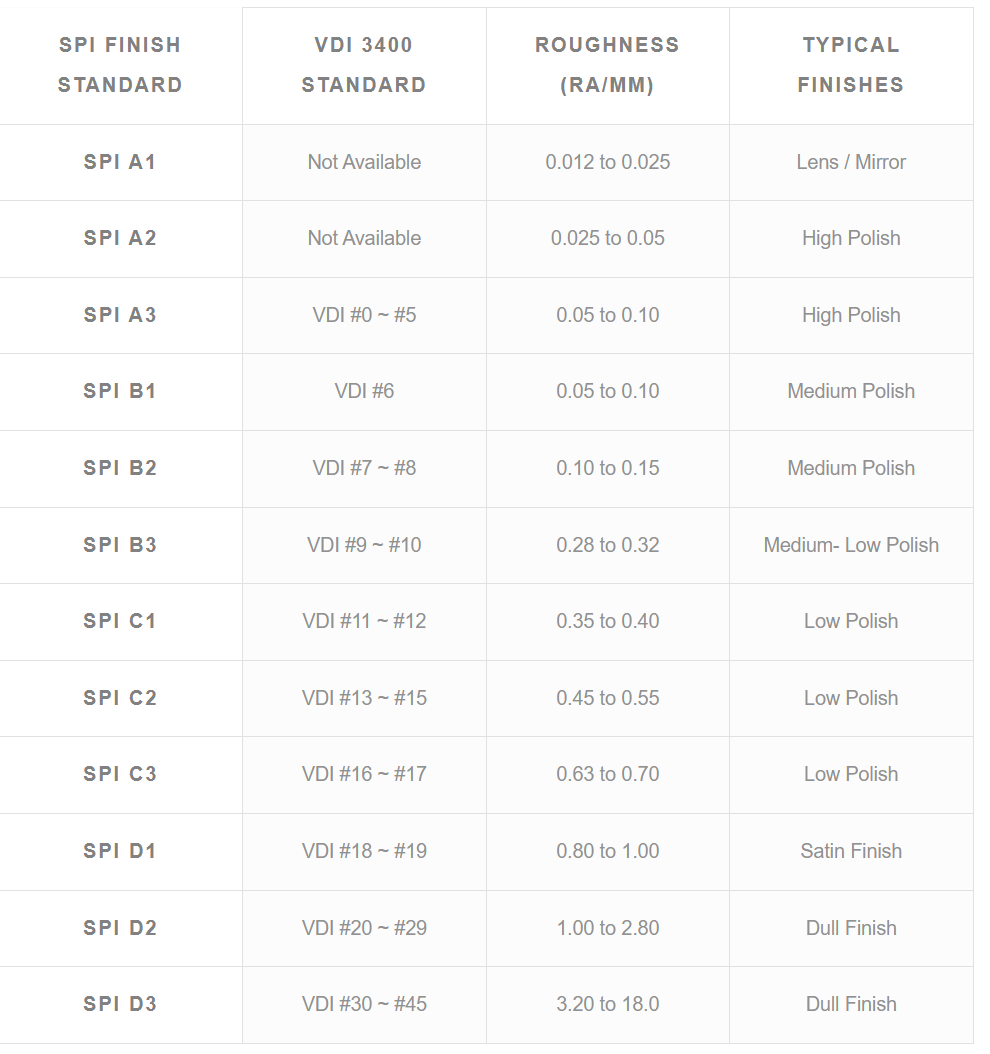

SPI surface finish

There are 12 SPI fnish grades of which can be achieved by below methods:

SPI A1, A2, A3 Grit Diamond (high gloss)

SPI B1, B2, B3 Grit Paper (semi-gloss)

SPI C1, C2, C3 Grit Stone (low gloss)

SPI D1, D2, D3 Dry Blast (Matte)

SPI A1, A2, A3 Grit Diamond (high gloss)

SPI B1, B2, B3 Grit Paper (semi-gloss)

SPI C1, C2, C3 Grit Stone (low gloss)

SPI D1, D2, D3 Dry Blast (Matte)

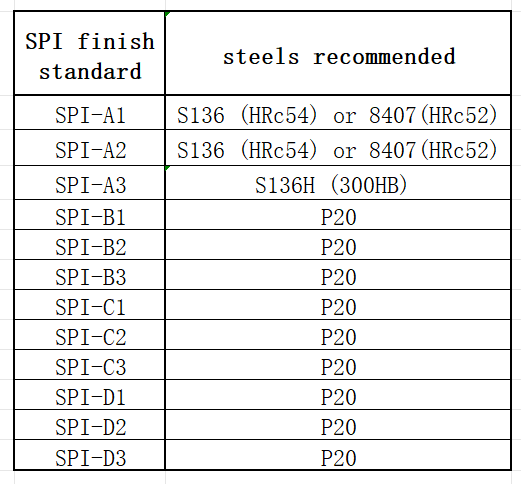

Steel selection GUIDE for surface finish

To achieve mirror fnish, you need to start from dull finish and by experienced mold steel tooling polishers.

Selection of steel is also a critical issue as steel grains quality affect feasible achievement.

Selection of steel is also a critical issue as steel grains quality affect feasible achievement.