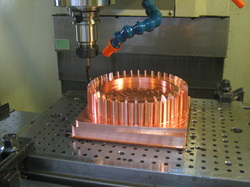

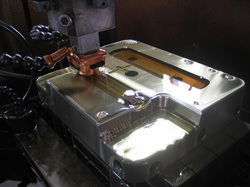

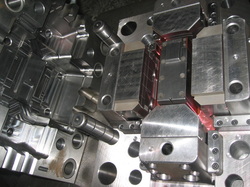

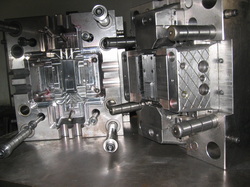

Mold Machining

High precison CNC milling and EDM/ WEDM machines to meet mold making and injection molding part request.

Make making manufacturing line is split into several manufacturing cells. Each cell has its own cell leader who is responsible for the mold progress plan, raw materials, sampling, quality and inspection.

Mold making lead times have been shortened due to machine work expertises and a reduction of work in progress.

All customers are benefiting from these working practices.

For "How it's made Plastic Injection Molds", please see video at bottom of Mold Making webpage.

Make making manufacturing line is split into several manufacturing cells. Each cell has its own cell leader who is responsible for the mold progress plan, raw materials, sampling, quality and inspection.

Mold making lead times have been shortened due to machine work expertises and a reduction of work in progress.

All customers are benefiting from these working practices.

For "How it's made Plastic Injection Molds", please see video at bottom of Mold Making webpage.

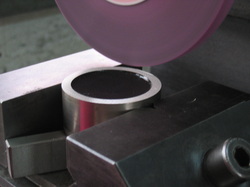

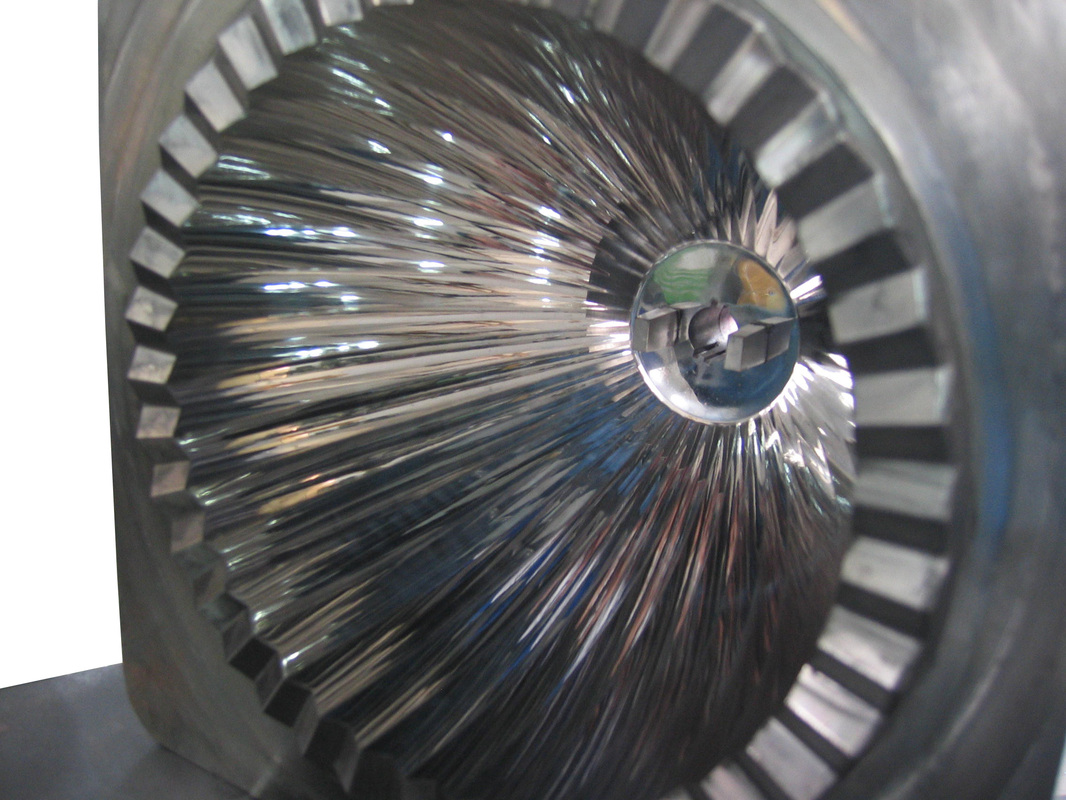

injection molding polishing

It is usually the last thing to be done.

It requires skillful technicians rubbing abrasive stones and diamond compound by hand on the finished cavities.

If it is possible, we can make use of things like ultra-sonic polishers and hand grinders.

Yet, most of the time, it gets down to hand work by a very skilled polisher. So far, there is just no way around it.

| plastic_injection_mold_testing_video.avi | |

| File Size: | 2323 kb |

| File Type: | avi |

Aluminium alloy CNC machined items

|

|

|