QUALITY:

For more details of tool qualification : Pls visit http://www.tsymolding.com/quality.html

tight tolerance plastic molding gears

worms and gears plastic parts (POM, Nylon)

You can be assured of tight quality control that guarantees an excellent product every time. TSY Molding Limited always pursues the best interests of our customers.

We never compromise the quality of the injection molds or injection molding

we produce. We define quality as total customer satisfaction. This drives us

to settle for nothing less than excellence in all aspects of our business as we continuously educate our people and improve our processes.

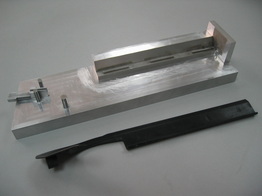

Optical measurement device

The staff and personnel will continually adhere to the systems and processes that support our ability to meet customer requirements and will strive to continually improve them.

TSY Molding Limited is committed to meeting our customer's

- expectations of quality,

- cost,

- on-time delivery, and

- continual improvement in all areas of the organization.

Quality Control

Quality assurance is an integral part of my company in today's competitive marketplace, and we take it very seriuosly. QA is a three-step process:

- A visual inspection is preformed by our trained machine operators in every part that is made the moment it comes out of

our machine using the parameters and critical dimensions set to you, our customer, to identify any rejects.

- The parts are then randomly inspected once again by our QA personnel at the machine once every hour, and any rejects

are logged.

- Finally, the acceptable parts are boxed, counted, and moved to our quality control department, where they are randomly

inspected once again, and the count is verified. The parts are then ready for shipment.

We are a plastic injection molding contract manufacturer with quality tool making and molding. We are with the full capability to work competently with our customers to transform their design into a finsihed product. From Concept to Completion at competitive price and short lead time with quality you want !

- A visual inspection is preformed by our trained machine operators in every part that is made the moment it comes out of

our machine using the parameters and critical dimensions set to you, our customer, to identify any rejects.

- The parts are then randomly inspected once again by our QA personnel at the machine once every hour, and any rejects

are logged.

- Finally, the acceptable parts are boxed, counted, and moved to our quality control department, where they are randomly

inspected once again, and the count is verified. The parts are then ready for shipment.

We are a plastic injection molding contract manufacturer with quality tool making and molding. We are with the full capability to work competently with our customers to transform their design into a finsihed product. From Concept to Completion at competitive price and short lead time with quality you want !