Major consideration for driving to successful Plastic Injection Part Design

Providing custom plastic injection molding solutions for companies whose plastic products and components require critical tolerances and exacting specifications. Our team of experts works closely with each customer, focusing on their unique needs, to find the global plastic solution that is the best match.

|

1. Field of Application

Outdoor of weather resistance, mechanical functions only, cosmetic outlook like color, surface appearance, medical parts or else as a complete consideration to driving correct plastic materials or else. |

2. Material Usage

It relates to final dims of part as different material with different shrinkage of which defined before tooling design start. |

|

3. Design Tool

Every option to look into to reduce tooling and piece cost while keeping your demand quality in the first position consideration. It is important but demand our technical experience and clients' patience. |

4. Manufacturing Process

Which production process do you selected in plastic injection molding ? @ Full automatic or labor intensive of which product life quantity,overall cost and demand quality break even analysis. @Any secondary operation to efficiently require to finish it. @ Any prototype service for preliminary engineering, production,marketing purpose. |

Every decision in the product development process affects cost. Cost reduction is the process used by companies to reduce their costs and increase their profits. Depending on a company's services or product, the strategies can vary. Companies typically launch a new product without focusing too much on cost. Cost becomes more important when competition increases and price becomes a differentiator in the market.

https://www.injectionmoldingsupplier.com/molding-defects.html

https://www.injectionmoldingsupplier.com/molding-defects.html

Plastic Injection Parts Product Design

Involve Injection Molder Early & Design Part for cost saving, short development time ......as well as manufacturability!!!

Design is one of the most important factors in avoiding part defects. It's your earliest opportunity to avoid mistakes that can be costly both in regard to time and budget later on.

@ Good design takes into account objectives including part function, aesthetic, manufacturability and assembly.

@ Working with a knowledgeable design engineer and involving your injection molder early will help you find solutions to meet the needs of your specific part.

Design is one of the most important factors in avoiding part defects. It's your earliest opportunity to avoid mistakes that can be costly both in regard to time and budget later on.

@ Good design takes into account objectives including part function, aesthetic, manufacturability and assembly.

@ Working with a knowledgeable design engineer and involving your injection molder early will help you find solutions to meet the needs of your specific part.

We provide plastic Part Design and Product Development services. The key to successful Plastic Product Design and Development is speed and experience. Our full suites of software provides a predictive tool for mold design analysis. Rapid Prototyping capabilities to reduce the product revision development cycle.

Speed to market is critical for the success of your project. To decrease program lead-times, TSY Molding Ltd. has created cross-functional engineering teams that have specialists in mold design, plastic injection mold processing and program management. Instead of working on your project in a sequential manner, each team member begins with their area of expertise when the project is launched. This results in early problem detection, better informed customers and reduced part design revisions.

When you combine highly skilled engineers with the proper Product Design and Development tools, you will get great results. That’s exactly what to expect when you work with TSY Molding Limited.

Speed to market is critical for the success of your project. To decrease program lead-times, TSY Molding Ltd. has created cross-functional engineering teams that have specialists in mold design, plastic injection mold processing and program management. Instead of working on your project in a sequential manner, each team member begins with their area of expertise when the project is launched. This results in early problem detection, better informed customers and reduced part design revisions.

When you combine highly skilled engineers with the proper Product Design and Development tools, you will get great results. That’s exactly what to expect when you work with TSY Molding Limited.

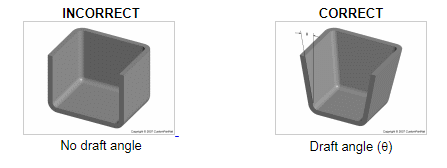

2. Draft Angle for Demolding

Draft angle must and should be applied on part design in direction of draw to avoid scatches when demolding.

Heavy texture requires larger draft.

Some plastic part product designers may overlook it, thus inducing poor quality molding parts in final with additional cost to remedy.

Heavy texture requires larger draft.

Some plastic part product designers may overlook it, thus inducing poor quality molding parts in final with additional cost to remedy.

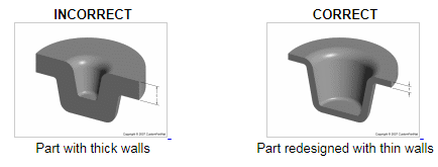

3. Uniform Wall Thickness

Material flowing across a sharp corner creates stress in the plastic, thus resulting in warp and dimensional instability.

Smooth corners that have a curve versus an angle are important. The radius should be consistent on the inside and outside of the wall creating a uniform thickness.

Smooth corners that have a curve versus an angle are important. The radius should be consistent on the inside and outside of the wall creating a uniform thickness.

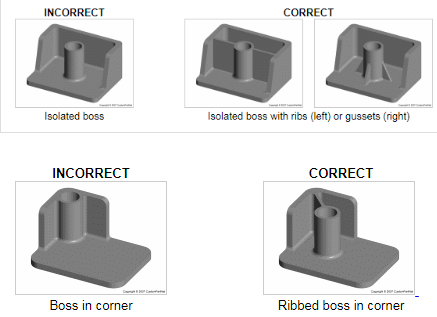

4. Bosses

4. Bosses

- Wall thickness of bosses should be no more than 60% of the main wall thickness.

- Radius at the base should be at least 25% of the main wall thickness.

- Should be supported by ribs that connect to adjacent walls or by ribs

- at the base

5. Save Manufacturing Costs

Your design should fit the injection molding process to be performed by machines and robotics The overheads are significantly reduced, this cost saving can easily be passed on to the customer. Using injection molding also ensures the parts manufactured hardly require any work after the production.

Select environment-friendly plastic material of which the scrap plastic generated during the production process can be reground and re-used.

Hence, the process generates very little waste.

Your design should fit the injection molding process to be performed by machines and robotics The overheads are significantly reduced, this cost saving can easily be passed on to the customer. Using injection molding also ensures the parts manufactured hardly require any work after the production.

Select environment-friendly plastic material of which the scrap plastic generated during the production process can be reground and re-used.

Hence, the process generates very little waste.

6. Material Selection

The material selection process can be as simple as an internet search for the material of an existing part already on the market, or as complex as identifying every single requirement and material property from the ground up. The first step is to define the requirements needed for your particular application. From there it's important to narrow the choices by process of elimination.

@ Do you need it to be rigid, flexible, elastomeric etc?

@ Is there a specific application? Medical?

@ What specific property requirements are there?

Sometimes the best thing to do is to not reinvent the wheel and do a search history for similar commercial applications if possible, then call up the material supplier for recommendations.

The material selection process can be as simple as an internet search for the material of an existing part already on the market, or as complex as identifying every single requirement and material property from the ground up. The first step is to define the requirements needed for your particular application. From there it's important to narrow the choices by process of elimination.

@ Do you need it to be rigid, flexible, elastomeric etc?

@ Is there a specific application? Medical?

@ What specific property requirements are there?

Sometimes the best thing to do is to not reinvent the wheel and do a search history for similar commercial applications if possible, then call up the material supplier for recommendations.

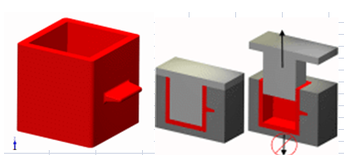

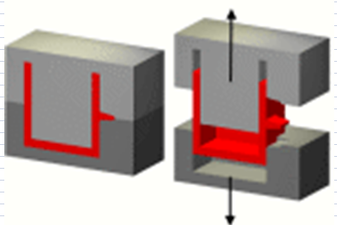

7. Gating and Ejection

Gate location is the area where the material will be entering into and filling the cavity of the part. It is important to keep in mind where you intend to gate your part and possibly make provision.

Some questions to consider are:

@Am I allowed to have a gate mark where I am envisioning my gate?

@ Is this gate at a location where the material will flow from a thick walled to a thin walled region of the part.

@ You must also account for ejector pin marks that will most likely show up on the underside of your molded part. If ejector marks are not allowed then that must be called out on your print so other ejection alternative can be considered.

Gate location is the area where the material will be entering into and filling the cavity of the part. It is important to keep in mind where you intend to gate your part and possibly make provision.

Some questions to consider are:

@Am I allowed to have a gate mark where I am envisioning my gate?

@ Is this gate at a location where the material will flow from a thick walled to a thin walled region of the part.

@ You must also account for ejector pin marks that will most likely show up on the underside of your molded part. If ejector marks are not allowed then that must be called out on your print so other ejection alternative can be considered.

8. Surface Quality

Difference in wall thickness due to ribs, bosses or other features causes sink marks. Ejection cause pin marks & scratches in the cosmetic surface.

Gates marks on the surface. Flashes from parting line or vents. Burn marks due to incomplete venting appear on surface.

Slides and inserts leave undesired witness lines on surface.Visible weld lines on surface.

Differences in color due to wall thickness variation.

Rough surface exposure for catching dirt, UV and chemical.

Difference in wall thickness due to ribs, bosses or other features causes sink marks. Ejection cause pin marks & scratches in the cosmetic surface.

Gates marks on the surface. Flashes from parting line or vents. Burn marks due to incomplete venting appear on surface.

Slides and inserts leave undesired witness lines on surface.Visible weld lines on surface.

Differences in color due to wall thickness variation.

Rough surface exposure for catching dirt, UV and chemical.