There are three main types of unscrewing molds: hydraulic, mechanical, and servo-driven.

Each type has its unique advantages and applications in the manufacturing process.

Each type has its unique advantages and applications in the manufacturing process.

Unscrew mold

Reliable &Creative Tooling Solution.

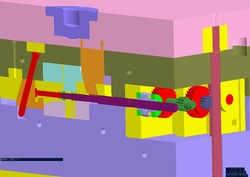

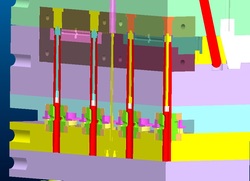

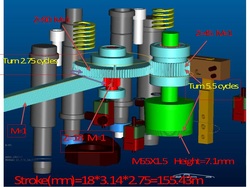

With Helical Spindle mechanical design,Mold Opening and Unscrewing at the same time, thus molding cost saving.

With Helical Spindle mechanical design,Mold Opening and Unscrewing at the same time, thus molding cost saving.

|

|

|

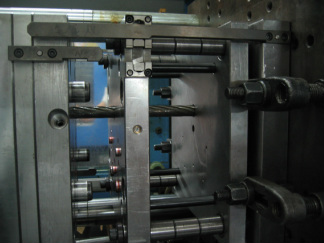

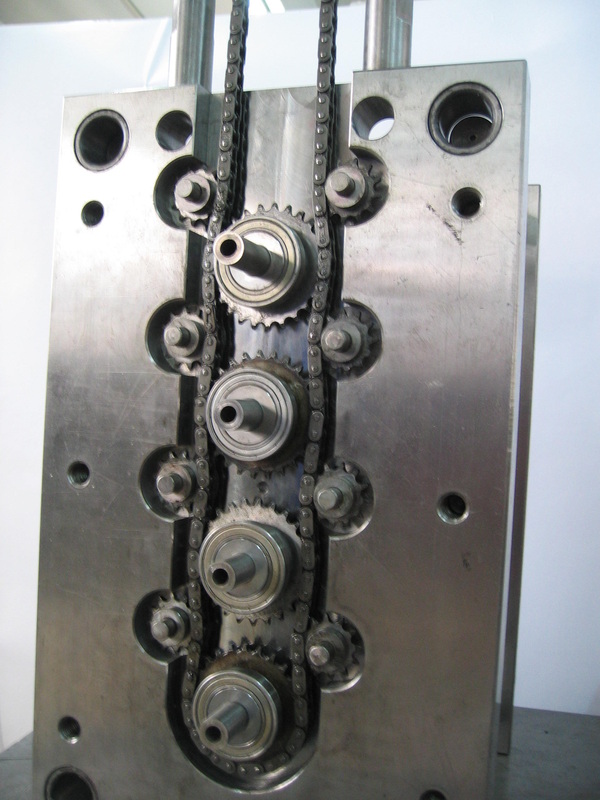

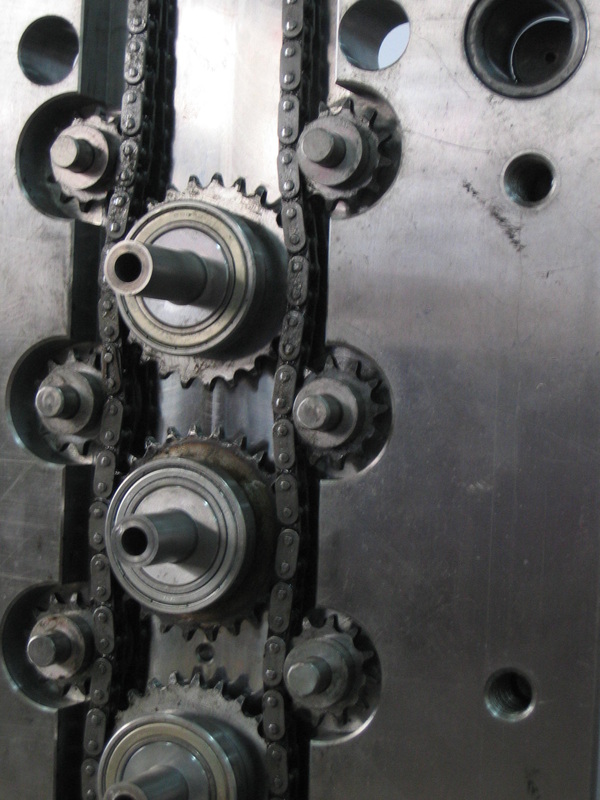

Rack and threaded core with hydraulic cylinder driving the rack

Hydraulic cylinder required force calculated in advance to ensure smooth and sufficient drive of gear train of force transmission. |

Rack and threaded core with gears ratio to unscrew part

Gear ratio is calculated to specific requirements with standard gears and rack internal mold components. http://www.injectionmoldingsupplier.com/blog.html |

Unscrewing plastic injection molding parts applications

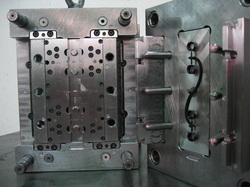

Many plastic parts have detailed threads whcih make ejecting the mold using bump-off methods virtually impossible. To avoid thread damage, such parts must be unscrewed from the mold. External threads can be parted and molded in both mold halves. Internal threads can be on collapsible cores or in unscrewing molds.

We design internal and external threads in custom plastic parts during plastic molding process through unscrewing molds. Injection molded threads are stronger than tapped threads, tighter tolerances and smoother than those produced by thread-cutting machining.

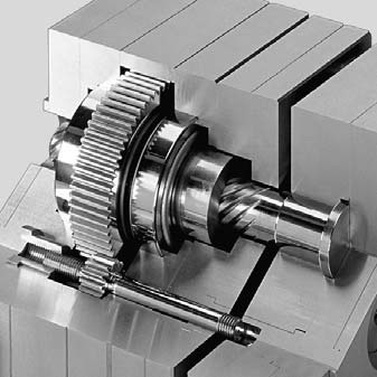

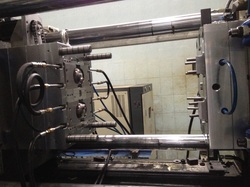

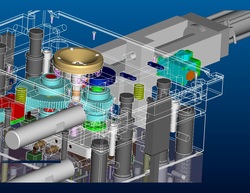

Our plastic injection design molds with : - integral gear core design

- hydraulic, mechanical , or electric driven designs

- cost effectives to clear molded parts quickly

- productive by utilizing robust carriage assemblies

- maximize performance of unscrewing molds

- avoid damaging threads

Applications in following major areas: - bottle caps and closures

- nuts and bolts

- sprinkler heads

- personal care / cosmetics packaging

- automotive parts

- consumer goods

The high operation speeds resulting from the quality mold design ,components and robustness of mechanisms integrated into our molds, make them the first choice for mass production. We provide free of charge advice and solid help to establish a reliable cost competitive strategy from the start of your projects. Our solutions are specifically adapted to meet your needs.

We design internal and external threads in custom plastic parts during plastic molding process through unscrewing molds. Injection molded threads are stronger than tapped threads, tighter tolerances and smoother than those produced by thread-cutting machining.

Our plastic injection design molds with : - integral gear core design

- hydraulic, mechanical , or electric driven designs

- cost effectives to clear molded parts quickly

- productive by utilizing robust carriage assemblies

- maximize performance of unscrewing molds

- avoid damaging threads

Applications in following major areas: - bottle caps and closures

- nuts and bolts

- sprinkler heads

- personal care / cosmetics packaging

- automotive parts

- consumer goods

The high operation speeds resulting from the quality mold design ,components and robustness of mechanisms integrated into our molds, make them the first choice for mass production. We provide free of charge advice and solid help to establish a reliable cost competitive strategy from the start of your projects. Our solutions are specifically adapted to meet your needs.

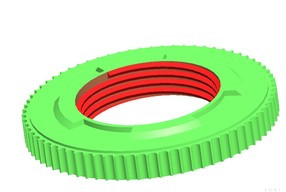

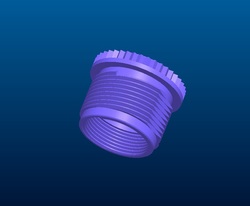

External thread precision plastic screw part

It can be demolded with 4 mechanical slides in tool design construction.

Screw external thread tool design (Cut thread and Full thread)

|

|

|