Mold Design with Mold Flow Analysis

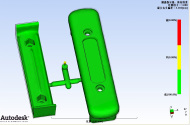

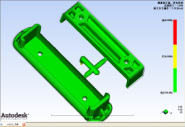

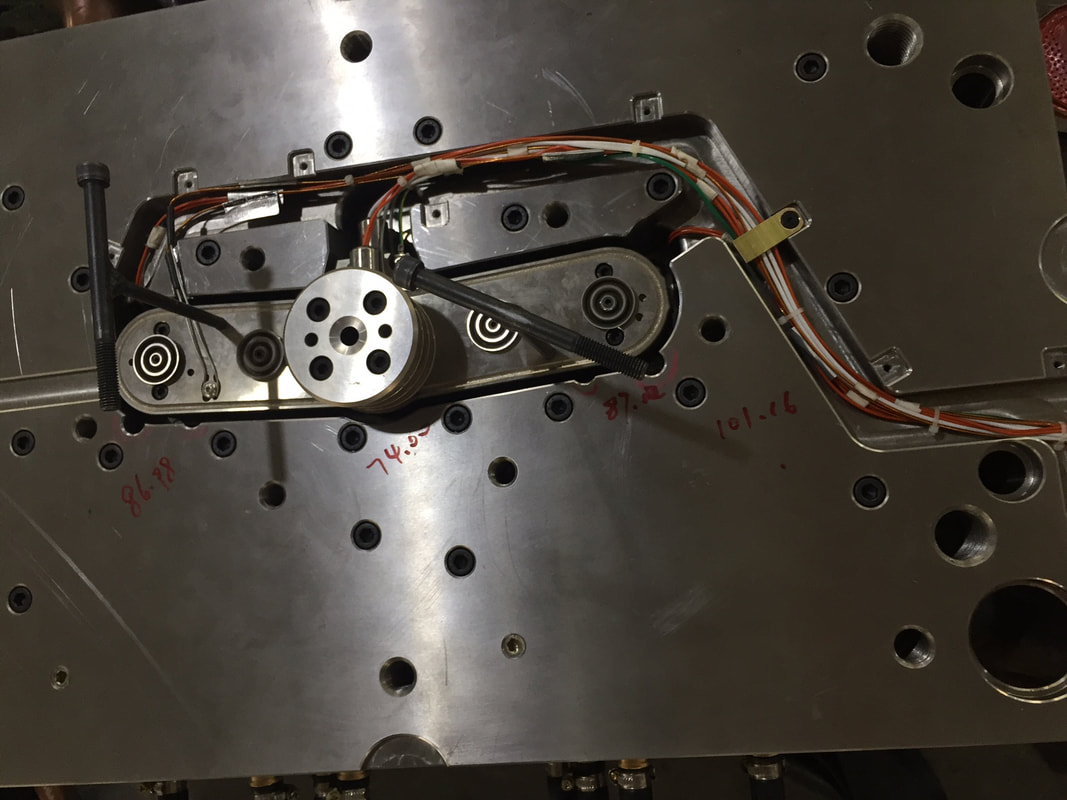

Mold tool designers utilize the latest software to take the customers CAD model directly into tool design.

A perfect, defect-free part begins with the mold. Building the tool likely represents the largest investment in the manufacturing process; therefore, getting it right is critical to the success of a project. Additionally, the volume of parts required, as well as the material they will be made of will help drive how and with what materials to create the mold.

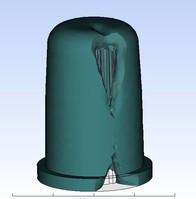

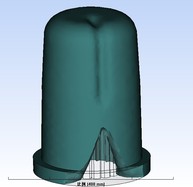

Injection molding moldflow analysis

It is used to simulate the complex of injection molded polymer melts and flows through the part cavity with data collated for interpretation. It helps to predict and eliminate potential molding problems prior to cutting of steel.

By suggesting alternative design options in combination with material selection and processing conditions evaluate, assist and optimize the design for the injection molding process.

|

injection molding into each caivty part

Please click and download moldflow filling analysis movie on the left.

| ||||||

Innovative design team

With extensive knowledge and experience of injection molding of engineering plastics, specialize in the design of complex single and multi impressive mold tools.

Using 2D/3D product and tool design software, we can offer our customers a fast response and a working partnership from initial component concept stage through to the design of production tooling.

Using 2D/3D product and tool design software, we can offer our customers a fast response and a working partnership from initial component concept stage through to the design of production tooling.

|

| ||||||||||||||||||||

Mold standard.

Many kinds of world-wide applied mould steels are used in our production. And our moulds are major for USA and Europe market. Most mould bases and standard components come from LKM. At the same time, we also can design mould according to customer's requirement, such as DME, HASCO standard. Below are some information for your reference.

Mould Steel:

*LKM : LKM2344SUPER,LKM2344,LKM818H,LKM838HLKM738HLKM2311LKM2312

*ASSAB(Sweden)IMPAX 718S,IMPAX 718H,STAVAX S136,STAVAX S136H

*DAIDO (Japan)PX88, NAK55, NAK80,DC11, DC53

*FINKL (America)P20HH, P20LQ; 420AUBERT & DUVAL

*(France)ADC3, SMV3W

Mould Base: DME, HASCO, FUTABA, LKM

Hot Runner:MOLD MASTER, Synventive, Master TIP, HUSKY, HASCO, DME, YUDO, INCOE, THERMOPLAY

Standard Parts:DME, HASCO, NEAREST ANSI STANDARD, NEAREST DIN STANDARD, LKM

Texture:Mold-Tech, Yick Sang

Many kinds of world-wide applied mould steels are used in our production. And our moulds are major for USA and Europe market. Most mould bases and standard components come from LKM. At the same time, we also can design mould according to customer's requirement, such as DME, HASCO standard. Below are some information for your reference.

Mould Steel:

*LKM : LKM2344SUPER,LKM2344,LKM818H,LKM838HLKM738HLKM2311LKM2312

*ASSAB(Sweden)IMPAX 718S,IMPAX 718H,STAVAX S136,STAVAX S136H

*DAIDO (Japan)PX88, NAK55, NAK80,DC11, DC53

*FINKL (America)P20HH, P20LQ; 420AUBERT & DUVAL

*(France)ADC3, SMV3W

Mould Base: DME, HASCO, FUTABA, LKM

Hot Runner:MOLD MASTER, Synventive, Master TIP, HUSKY, HASCO, DME, YUDO, INCOE, THERMOPLAY

Standard Parts:DME, HASCO, NEAREST ANSI STANDARD, NEAREST DIN STANDARD, LKM

Texture:Mold-Tech, Yick Sang