- .Does the supplier have the manufacturing capabilities you need? See for yourself and visit the factory floor if possible.

- Does it have the manufacturing speed and capacity to respond to quick-turn orders during product development, market launch or production phases?

- Does it have minimum part order? Many production houses have relatively large minimum part orders, which can be a risky upfront financial investment if only low volumes of parts are initially needed. Look for a service bureau with no minimum part restrictions.

- Does it have the level of quality control you need? A medical-grade supplier’s quality control should be excellent but that would add expense to a commercial-grade product that may not need such an elevated level.

- Does it work with your project’s materials? Service bureaus typically stock with the widest selection of materials on hand and have the most expertise in using them. They often accept most customer-supplied materials as well.

- Does it offer design support? If you’re not a manufacturing expert, advice or feedback on the manufacturability of your project may be in order.

|

0 Comments

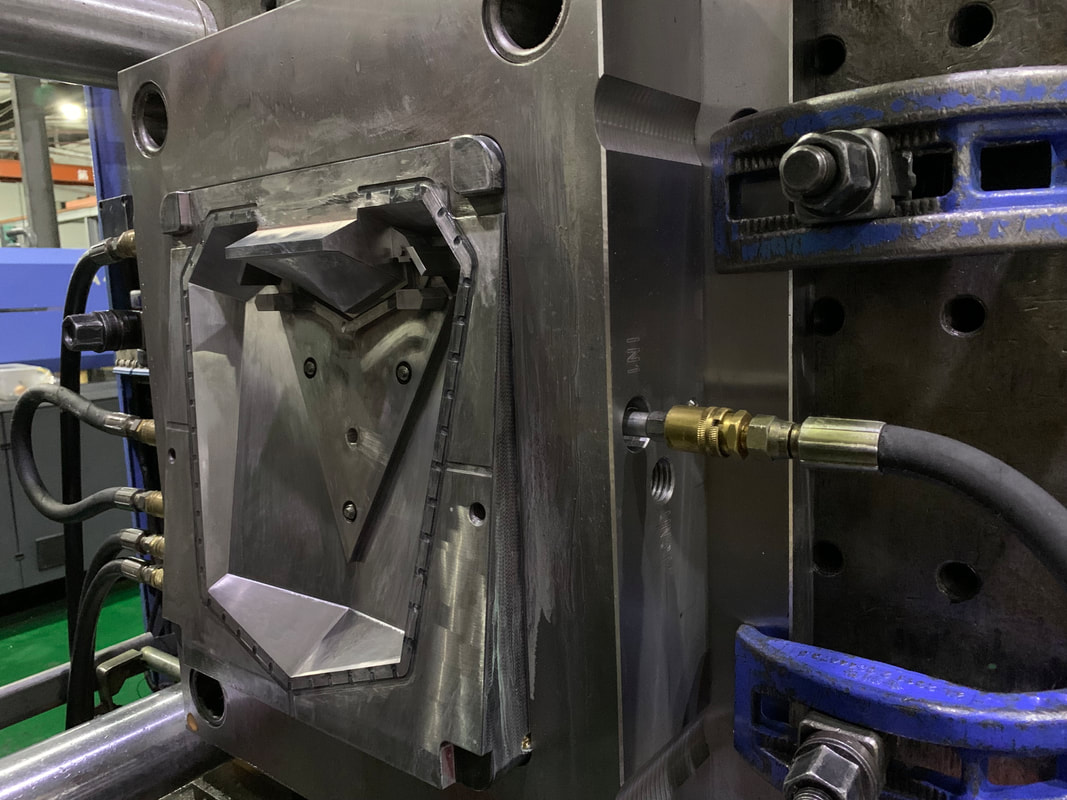

To find a good plastic injection mold maker supplier is difficult, not only in China, but all over the world.

You must firstly try to build the partnership with the supplier. The expectation and understanding would be very important for the success, It would be very helpful for your mold supplier understood your requirements and expectations. Whether you’re looking for short run production, rapid tooling or prototyping services we can help you find the best solution and deliver it quickly and efficiently.

1. We have the experience and equipment to provide unparalleled speed, flexibility and support. 2. We use our exceptional molding expertise to provide comprehensive technical guidance and tooling options for your project. 3. We don’t just send a price estimate for a new project. We pride ourselves on working closely with you from the start, making sure job specifications align with your project goals. 4. We’re also proud of our speed, providing short turnaround on injection molding services without sacrificing quality or precision. 5. We’re constantly refining our production process, implementing new ways to reduce inefficiencies and shorten lead times for our customers. TSY Molding Ltd isn’t like other plastic injection mold making and molding facilities. Plastic Injection Molding local supplier is always better than using an offshore supplier ?14/2/2024 Local supplier is always better than using an Offshore Supplier ?

@ Working with an offshore supplier include:- Manufacturing quotes often leave out costs associated with shipping of which you can assigned your own shipper within your budget. @ Assurance Quality:- Buyer must speak up to an experience manufacturers often guide you advice for sufficient quality control results in high-quality finished products for your brand’s reputation. @ Design Expectations:- Manufacturers often ask more include design features that exceed your expectations. For example, often require automatic operation to save labour cost. @ Design Time:- Preliminary study with analysis report communicated before designs start of which often right to exact requirement at the first submission within the shortest time. @ Trials and Evaluation up to spec. before final shipment:- It saves a lot of costs of finding relevant technicans at buyers site. Conclusions: Only if you can find good words of mouth from others can guide you well and cost saving from suppliers in split of sitting next to door local suppliers or in distant offshore suppliers of which plastic injection molding solutions send to your inbox immediately. Mold Complexity is a major impact of tooling cost. Many delicate undercuts made demanding design and experienced mold-building process A good tool design can ensure easiler production and less maintenance over an extended period, thus lower all hidden cost Steel materials selection. Choosing correct steel material meaning relevant steel for your products life. It dosen't make cost effective if low volume, say 1k, using high quality steel, say over 100k, tool life. Cost saving in mold ?

Family mold with interchangeable inserts for different versions It may be save cost if prodiction volume is low. Yet, hidden cost will be high if time constraints in production. Need good tooling design from start before machining to assembly. Procedures :

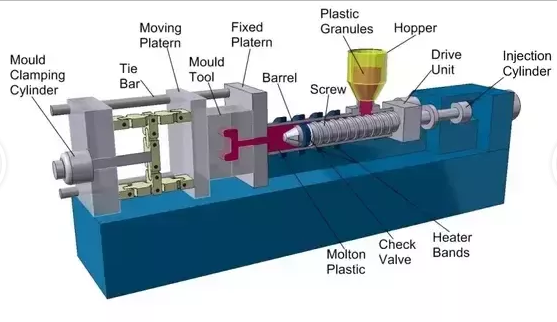

1,Mold Flow to optimum the best injection locations in view of - warpage for acceptable product strength - weldlines/potential air trapped locations 2. Cooling 3. Machines size 4. Tool steels selection For quality plastic parts with the appropriate durability, clients need to invest appropriately.2/5/2019 Mold vendors take the required specifications from their customers and produce a mold. This mold is then provided to the injection molding company to manufacture the parts.

If the part produced is not designed with the correct plastic materials, final products can fail in testing or in consumer’s hands. Commonly enough, failure of injection molded parts is not an issue of bad practice on anyone’s part, but rather due to a reliance on cheap, low-durability plastic materials in order to obtain a lower cost. For quality parts with the appropriate durability, clients need to invest appropriately. Selection of plastic material is important for early product design stage rather than trial with error.

Below is plastic material selection guide lines for your consideration:- http://www.injectionmoldingsupplier.com/injection-molding.html Plastic Injection Molding Beat your deadlines with our quick-turn injection molding services

What makes us Different?

When you’re looking for short-run or injection molded parts, time is usually of the essence — but so, as always, is quality. Prototype injection molding lets you enjoy both benefits, meeting your fast turnaround needs through a process that provides some of the most reliable, high-quality products available. With serve demand, we setup new factory site for cost saving, efficient and short delivery time to client. 1) It's precision

Plastic injection molding is such a precise method that it can fabricate nearly any type of plastic part. 2) It's quick While the speed depends on the complexity of the mold itself, generally only about 15 to 30 seconds pass between cycle times. 3) Labor Saving. Injection molding equipment typically runs with a self-gating, automatic tool to keep operations streamlined and production ongoing, requiring minimal supervision. 4) It's resourceful. .That's because a) only as much plastic as is necessary is used to create the part and b) excess plastic can be ground up and recycled after use. 5) Flexibility. It's simple to change the type of material that is being produced as well as the color that the product is being produced in. 6) Creating high-strength components. Plastic injection molding is an ideal process for industries or products where parts need to be strong 7) Good finished appearance. Plastic injection molding is a process, for the most part, where produced parts need little to no end finishing. That's because all parts that come out of the mold are about the closest thing to a finished appearance. 8) Cheaper than plastic machining, long-term. The initial creation of a mold can be expensive, with the cost being a few thousand dollars. But once the mold is created you can create a very large volume of plastic components at a minimal cost. 9) It's widely used. Plastic injection molding is one of the most popular plastic producing processes.  @We meet deadlines. @We work to budgets. @We craft detailed commercial proposals with authoritative time planning. @We understand the cost to manufacture products and the prototyping and production techniques available. @We understand the complex relationships between people, business, brand and technology. @We seamlessly integrate industrial design and innovative engineering to create effective,profitable, award winning product solutions. @We have immediate technical response by e-mail, wechat or phone call. @ We listen to clients with patience and professional technical feedback. @ Free of charge FDM report, mold flow @Contact: [email protected] www.injectionmoldingsupplier.com .Clamping force of injection machine minimization. GREAT IDEA!

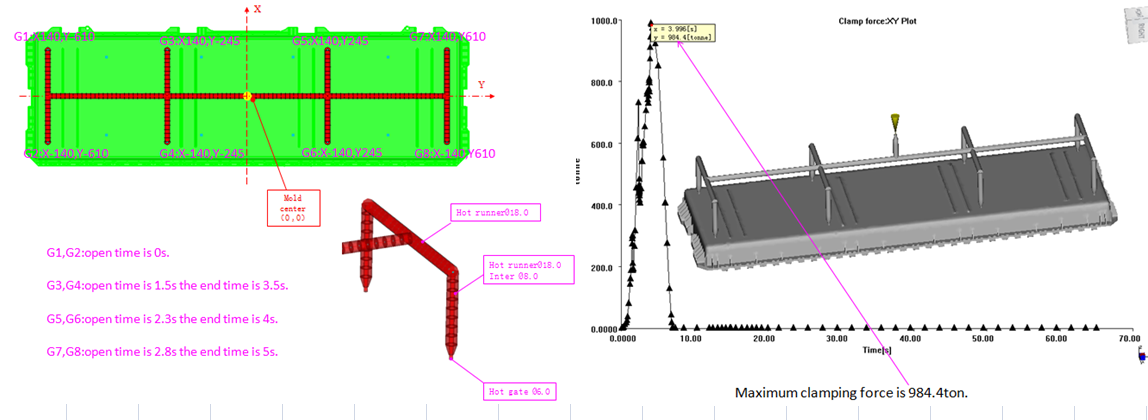

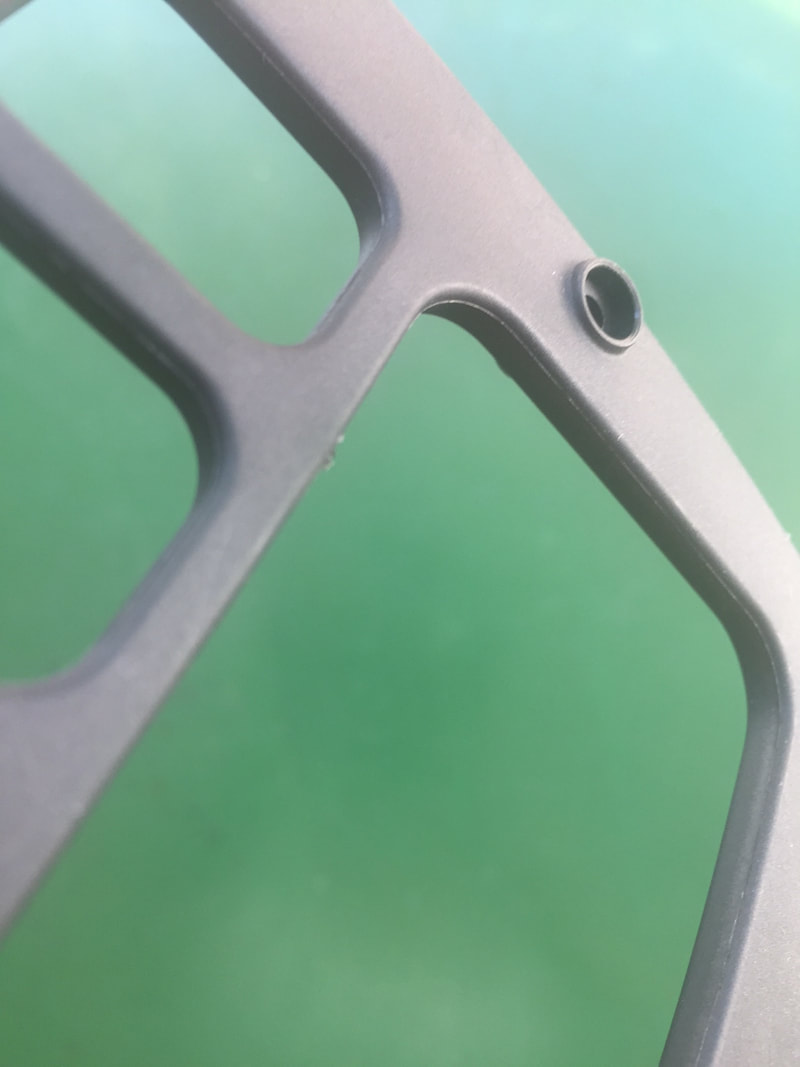

It can be slightly reduced with multi-drops (from 6 to 8 drops) hot valve gates together with by controlling in a defined sequential time respective gates of opening and closing. A good idea to reduce cost in the long production run ! http://www.injectionmolderchina.com/  Wall Thickness of plastic products design is important. Non-uniform wall sections can contribute to warpage and stresses in molded parts. @ Sections which are too thin have a higher chance of breakage in handling, may restrict the flow of material and may trap air causing a defective part. @ Too heavy a wall thickness, on the other hand, will slow the curing cycle and add to material cost and increase cycle time. Generally, thinner walls are more feasible with small parts rather than with large ones. The limiting factor in wall thinness is the tendency for the plastic material in thin walls to cool and solidify before the mold is filled. The shorter the material flow, the thinner the wall can be. Walls also should be as uniform in thickness as possible to avoid warpage from uneven shrinkage. When changes in wall thickness are unavoidable, the transition should be gradual and not abrupt  We are looking for co-operation with you as TSY Molding Limited is a solid factory of plastic injection tool making , molding services or even more. We can make @ SLA or 3D print prototypes for your evaluation, @ DFM analysis reports, @ tool design, @ plastic injection mold making, including export tools, @ plastic parts production, @ mechanical assembly to products in markets, @ logistic arrangement to your door as to where,when and quantity you want. Pls send your RFQs for ,free of charge, budget estimation and proposals. E-mail : [email protected] website : www.injectionmoldingsupplier.com Description:

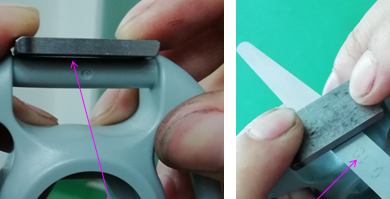

The molded component is twisted, uneven, or bent shape where one was not intended. Warping is usually caused by non-uniform cooling of the mold material. Different cooling rates in different parts of the mold cause the plastic to cool differently, thus creating internal stresses. These stresses, when released, lead to warping. Solutions: @Ensure that the cooling time is sufficiently long and that it is slow enough to avoid the development of residual stresses being locked into the part. @Design the mold with uniform wall thickness and so that the plastic flows in a single direction. @Select plastic materials that are less likely to shrink and deform. Semi-crystalline materials are generally more prone to warping. Design for manufacturability is also known as design for manufacturing or DFM in short.

In the industry of plastic injection molding. DFM is more often like”design for moldability“, as mold makers focus on the feasibility of injection molding process. A report (normally in PPT) on DFM to show customers how to optimize part design, our molding solution and potentially problem areas of your plastic parts. It is free of charge.

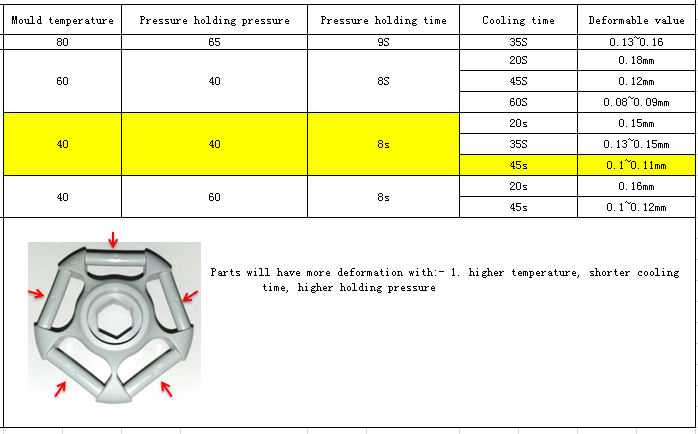

Plastic Part Deformation in control from START in plastic part design !?

Plastic design, mold design, plastic materials selection and injection parameters are the 4 keys in affecting final plastic part deformation. The plastic part design is dominated the others. With uneven wall thickness and differential shrinkage at different locations: - mold design and raw plastic materials will make up a little effect, - injection molding parameters setting will then be more demanding for reducing deformation of parts under constant part weight and tool gating size by means of @ lower mold temperature @ longer cooling time @ lower holding pressure |

AuthorWorking in plastic injection mold making and molding over 20 years. Archives

March 2024

Categories

All

|

RSS Feed

RSS Feed