"Dear S.Y.,

How are you? Great hearing from you. Indeed I remember your kind support in HK. I have commented

it to my team there and in my next trip to China we will for sure have a good chat while having dinner and drinks. Your kindness is such that is not very usual these days so a big thank you from me!

As for your request what your customer is requesting is for you to plan a draft reserve for a texture with 0,004 depth, with MT (Mold-Tech) reference number not yet defined. What is not clear is whether he is working in imperial or metric system and thus please make sure you confirm before proceeding.

Below the different draft recommendation for imperial and metric:

Texture depth vs draft:

1. If Imperial: 0,004 inches = 0,1 mm = aprox. 100 microns

Recommended draft in favorable shrinkage conditions:

9 degrees (1,5 degrees for natural demoulding + 1 degree per each 13 microns depth)

2. If metric: 0,004 mm = aprox. 40 microns

Recommended draft in favorable shrinkage conditions:

4,5 degrees (1,5 degrees for natural demoulding + 1 degree per each 13 microns depth)

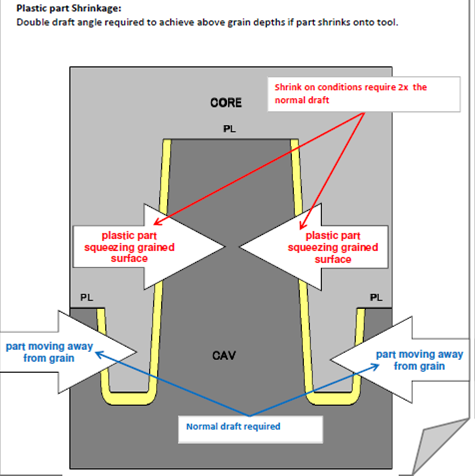

Please check below sketch. It shows draft needs versus shrinkage conditions. If the part has a

geometry that shrinks on to the grained surfaces than our recommendation is to double the minimum recommended draft.

Hope to see you soon. All the best until then!

Paulo Vilaca, Mold-Tech, Standex Engraving Group"

|

1 Comment

8/3/2022 11:18:06

It's great that you elaborated on the importance of confirming the process to prevent making mistakes. My best friend is looking for a damaged mold texture repair for their products that have been damaged during shipment, and he asked if I had any recommendations. Thank you for the informative article; I'll be sure to inform him that he may visit a reputable damaged mold texture repair service for assistance with the wear and tear of their products.

Reply

Leave a Reply. |

AuthorWorking in plastic injection mold making and molding over 20 years. Archives

March 2024

Categories

All

|

RSS Feed

RSS Feed